Expert Digitizing for Embroidery: Rapid and Reliable Service

Expert Digitizing for Embroidery: Rapid and Reliable Service

Blog Article

Understanding the Needlework Digitizing Process: Your Ultimate Guide

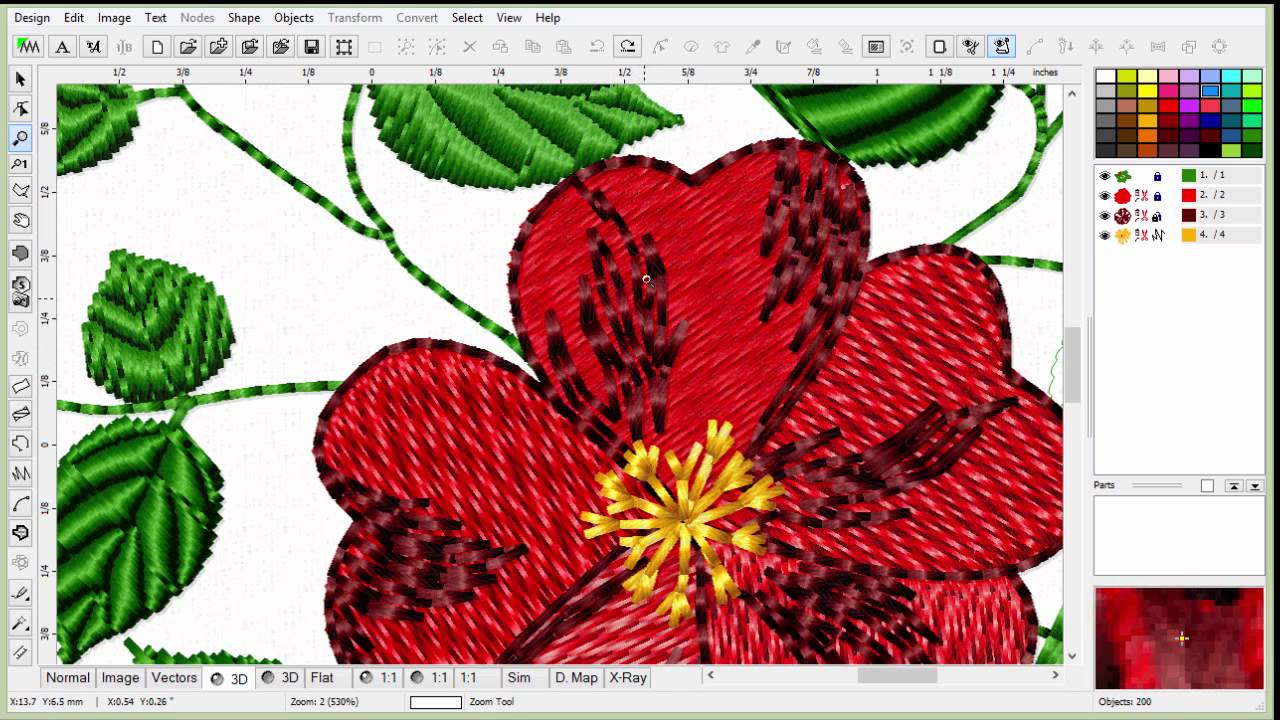

Embroidery digitizing is a thorough craft that requires precision and experience to equate elaborate styles right into electronic formats for equipment needlework. As craftsmens begin on this trip to understand the needlework digitizing procedure, a comprehensive understanding of the essentials establishes the foundation for excellence. Nonetheless, past the fundamental knowledge lies a realm of innovative software, specialized devices, and nuanced methods waiting to be explored. By delving right into the subtleties of digitizing, one can unlock a globe of imaginative opportunities and boost their embroidery jobs to brand-new elevations.

Recognizing Needlework Digitizing Fundamentals

Needlework digitizing basics create the structure whereupon elaborate designs are translated right into machine-readable layouts for exact stitching. This preliminary step in the embroidery digitizing process is essential for ensuring that the last embroidered product is a devoted representation of the initial layout. Understanding embroidery digitizing essentials involves understanding essential concepts such as stitch kinds, sew direction, thickness, underlay, and pull payment.

Sew kinds play a crucial duty in identifying the aesthetic and textural end result of the stitched style. By selecting the proper stitch type, whether it be satin, fill, or running stitch, digitizers can achieve the preferred effect and improve the general high quality of the needlework. Furthermore, sew instructions influences the flow and dimension of the layout, while density identifies the spacing and insurance coverage of the stitches.

Moreover, rug sewing gives security to the style by protecting the textile and preventing distortion during the embroidery procedure. Pull settlement is one more crucial factor to consider to counteract the all-natural tendency of material to agreement when sewn. Mastering these embroidery digitizing basics is fundamental for creating professional-quality embroidered items.

Picking the Right Digitizing Software

Choosing the suitable digitizing software program is a crucial decision that substantially impacts the effectiveness and quality of the embroidery digitizing procedure. Digitizing for Embroidery. When choosing the right digitizing software application, it is vital to think about aspects such as the complexity of layouts you plan to produce, the user-friendliness of the software, the degree of consumer support provided, and the compatibility with your embroidery equipment

There are numerous digitizing software options available in the marketplace, ranging from basic programs for newbies to advanced software for specialist digitizers. Some prominent selections consist of Wilcom EmbroideryStudio, Hatch Embroidery Software, and PulseID. These software supply a large range of devices and features to aid you produce complex designs easily.

Prior to choosing, it is recommended to discover the various software program choices via free tests or trials to identify which one best matches your needs. In addition, checking out testimonials and looking for suggestions from skilled digitizers can provide useful insights right into the staminas and weaknesses of each software (Digitizing for Embroidery). By meticulously evaluating your requirements and comparing the attributes of various digitizing software program, you can make an educated option that enhances your needlework digitizing process

Digitizing Tools and Methods

Optimizing Layout Setup for Needlework

Grasping the intricacies of style setups is essential in achieving optimal cause the needlework digitizing procedure, structure upon the structure laid by understanding digitizing tools and techniques. When maximizing layout settings for embroidery, it is vital to consider elements such recommended you read as stitch kind, density, underlay, pull settlement, and registration. Stitch type choice influences the total appearance and feeling of the design, with alternatives like satin, fill, and running stitches providing different textures and impacts. Thickness refers to the spacing and thickness of stitches, impacting the layout's insurance coverage and longevity. Correct rug sewing gives security and prevents material distortion, specifically for complex layouts or on stretchy materials. Draw compensation readjusts for material stretch during stitching, making certain accurate layout duplication. Enrollment settings straighten different components of the layout accurately, preserving general style integrity. By fine-tuning these design settings, embroiderers can boost the top quality and precision of their embroidered check my source productions.

Troubleshooting Common Digitizing Issues

When running into typical digitizing issues during the needlework process, it is necessary to comprehend the root creates and apply reliable options promptly. One usual trouble is stitch thickness concerns, where stitches might be as well thick, triggering the material to pucker, or also thin, bring about spaces in the design. Readjusting the stitch thickness settings in the digitizing software program can assist fix this issue.

Another frequent obstacle is thread breaks during the embroidery process. This can happen because of various factors such as incorrect stress settings, boring needles, or utilizing low-quality thread. Ensuring appropriate maintenance of the needlework equipment, including normal needle changes and tension modifications, can minimize the occurrence of string breaks.

Furthermore, design enrollment mistakes can result in misaligned aspects within the embroidery design. Inspecting the layout positioning in the digitizing software and making required changes before stitching can help in preventing this issue. By resolving these common digitizing concerns immediately and effectively, you can ensure a smoother embroidery process and top quality ended up products.

Final Thought

To conclude, understanding the needlework digitizing process requires a strong understanding of the basics, the best option of software, and knowledge of devices and techniques. Optimizing design setups and troubleshooting common digitizing issues are vital actions in ensuring high-grade needlework outcomes. By complying with these details these actions carefully, one can accomplish accuracy and performance in the digitizing process.

Report this page